Plastics Recycling Plants Market Growth CAGR Overview

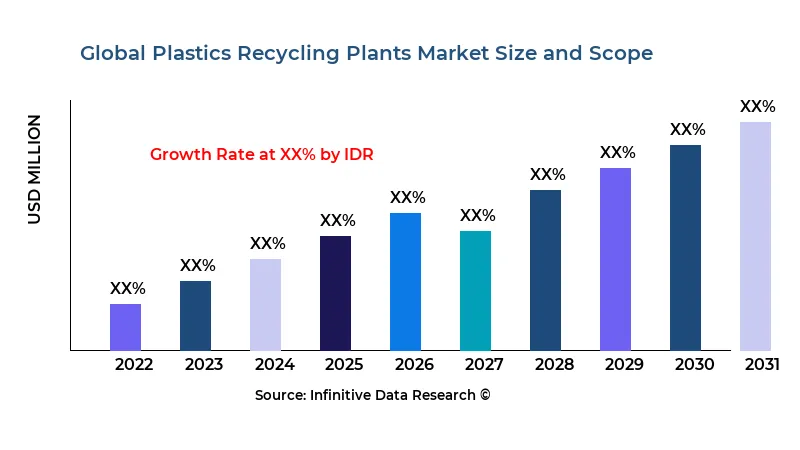

According to research by Infinitive Data Research, the global Plastics Recycling Plants Market size was valued at USD 16.6 Bln (billion) in 2024 and is Calculated to reach USD 24.1 Bln (billion) by the end of 2032, growing at an anticipated compound annual growth rate (CAGR) of 7.3% during the forecast period 2024 to 2032. This projected growth is driven by its increasing adoption across Machinery & Equipment industries such as Food, Chemical, Daily NecessitiesThe plastics recycling plants market is undergoing significant transformation as global environmental concerns continue to intensify and regulatory frameworks evolve. Over recent years, governments have introduced stricter environmental policies which have accelerated investments in advanced recycling technologies. This market has witnessed diversification in processes—from mechanical recycling to chemical recycling methodologies—each enabling more efficient reuse of plastic waste and bolstering market confidence. The drive towards sustainability in manufacturing practices has further fueled investments and research, spurring innovation in recycling technologies that optimize energy efficiency and reduce waste.

Shifts in consumer awareness and increasing demand for sustainable products have deeply influenced market dynamics. In regions where sustainability is prioritized, consumer behavior has prompted companies to upgrade their recycling capacities and adopt state-of-the-art plant facilities. Major industry players are exploring strategic partnerships with government and non-government stakeholders to leverage infrastructure investments and secure long-term contracts. This trend is complemented by the rise of circular economy practices that advocate for the reprocessing and reintegration of plastic waste into manufacturing pipelines, promoting a seamless link between production and resource recovery.

International trade policies and local environmental regulations have also exerted a profound influence on market operations. As nations actively participate in global initiatives to minimize plastic pollution, there has been a concerted push towards harmonized standards that facilitate cross-border technology sharing and process optimization. Amid this evolving regulatory landscape, market participants are rapidly adapting their operational models to meet both compliance requirements and consumer expectations for high-quality, recyclable plastics. These shifts encourage investment in modern plant infrastructures that are more adaptable to fluctuating waste streams and evolving industry demands.

Technological innovation remains at the forefront of market dynamics, with significant research being dedicated to improving process yields and reducing operational costs. Companies are investing in automation, robotics, and sensor-based sorting systems that enhance the overall efficiency of recycling operations. Such advancements not only refine the quality of recycled outputs but also improve plant safety and reduce human intervention. As the interplay between technological progression and sustainability becomes stronger, market players are continuously rethinking their strategies to harness these advancements and secure competitive advantages, fostering a resilient and future-focused recycling industry.

>>> Understand The Key Trends Shaping This Market:- Download PDF Sample

Plastics Recycling Plants Market Growth Factors

The plastics recycling industry is primarily driven by the global emphasis on sustainability and resource conservation. One of the major factors propelling market growth is the intensification of legislation aimed at curtailing plastic waste. Countries around the world are implementing bans on single-use plastics and mandating higher recycling quotas, thereby creating a conducive environment for expansive investment in recycling plant infrastructure. This regulatory support is coupled with public and private funding initiatives that have significantly lowered barriers to entry for emerging technologies within the recycling sector.

Another pivotal growth factor is the advancement in sorting and decontamination technologies that have made recycling processes more efficient and environmentally friendly. These technological breakthroughs enable recycling plants to handle a wider variety of plastic types and degrade contaminants to acceptable levels, thereby increasing the volume of recyclable material. Additionally, improved recovery rates contribute directly to economies of scale, making recycling processes economically viable even for lower-margin recycled products. This convergence of technology and environmental necessity is leading to increased market adoption and higher production throughput across global operations.

Economic factors also contribute significantly to the growth of plastics recycling plants. As raw material prices fluctuate and supply chain uncertainties become more prevalent, manufacturers are increasingly seeking cost-effective and secure sources of recycled plastic feedstock. This economic incentive aligns well with government policies that encourage sustainable practices. Moreover, the integration of recycling processes within existing production lines has proven beneficial in reducing dependency on virgin plastic, thus providing a buffer against market volatility and ensuring long-term cost savings for industrial players.

Global environmental concerns and resource depletion have further set the stage for robust growth in this market segment. With finite resources being a significant constraint on long-term industrial output, reliance on recycled materials is now not just an environmental imperative but also an economic strategy. Increased awareness among industries regarding the benefits of a circular economy—where waste is minimized and resources are reused—drives investment into upgrading recycling plant capacity and operational efficiency. This trend is expected to continue as industries across the globe integrate environmental considerations into their business models, ensuring steady market growth over the next decade.

Market Analysis By Competitors

- Coparm

- Bezner

- NM Heilig

- Kiverco

- CP Manufacturing

- Metso

- PCI Equipment

- Krause Manufacturing

- MHM Recycling

- Komptech Americas

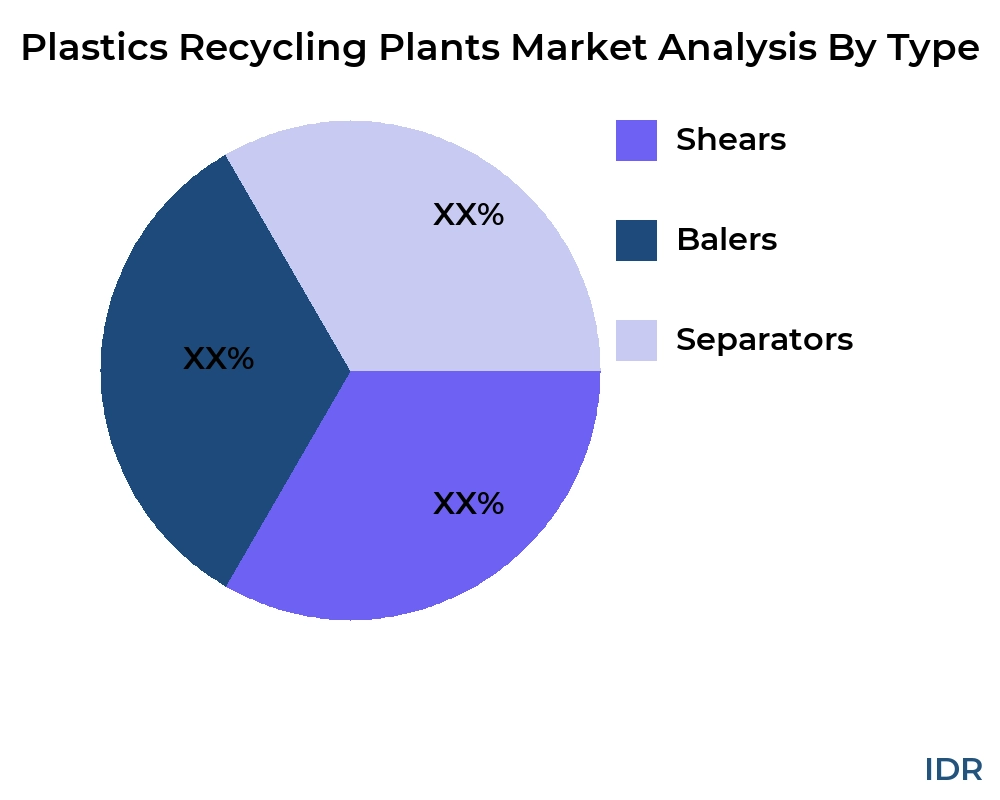

By Product Type

- Shears

- Balers

- Separators

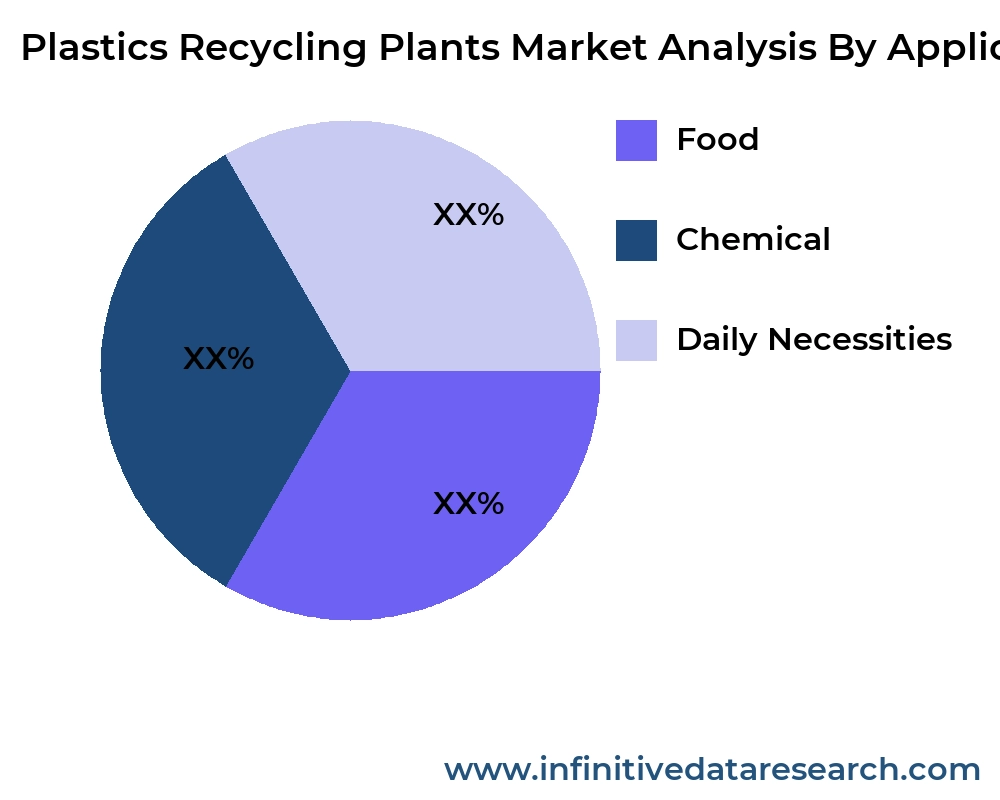

By Application

- Food

- Chemical

- Daily Necessities

>>> Understand The Key Trends Shaping This Market:- Understand The Key Trends Shaping This Market:-

Plastics Recycling Plants Market Segment Analysis

Distribution Channel:

Distribution channels in the plastics recycling plants market are undergoing transformation with the integration of both traditional supply chain methods and modern direct-to-consumer models. Industrial recycling equipment is increasingly being supplied directly by manufacturers to large-scale production facilities, while smaller units are commonly accessed through specialized distributors. The channel structure supports a robust network of logistics and after-sales services, ensuring that recycling plant components are readily available and technically supported. The continuous growth in demand for recycled plastics motivates significant collaboration between distributors and recycling plant operators, leading to enhanced product availability and optimized support services that bolster market penetration and sustained distribution efficiencies.

Compatibility:

Market segments are increasingly demanding versatile recycling plant systems that seamlessly integrate with existing waste management infrastructures. Manufacturers are striving to design plants that are adaptable to a variety of plastic types and compatible with multiple downstream processing systems. The focus on compatibility has led to the development of modular plant designs that allow for incremental investments and easy upgrades as technology evolves. This compatibility not only ensures smoother integration with current industrial systems but also facilitates rapid implementation in regions with diverse recycling requirements. As sustainability standards become more stringent, the need for compatibility drives ongoing research and product development efforts that cater to evolving industry specifications and technological norms.

Price:

Pricing in the plastics recycling plants market is an influential factor that determines the competitive positioning of different vendors. Market participants often adopt competitive pricing strategies that balance cost, quality, and technological sophistication. The price segment analysis takes into account not only the initial capital expenditure but also the long-term operational and maintenance costs associated with modern recycling plants. Economies of scale and technological innovations have helped bring down production costs, making high-performance plants more affordable for mid- and small-scale operations. The dynamic pricing environment encourages manufacturers to offer tiered pricing structures and flexible financing options designed to meet the budgetary constraints and operational requirements of a diverse customer base, thereby fostering broader market adoption.

Product Type:

The diversity of product types within the plastics recycling plants market is key to its expansion, as different plant configurations are tailored to address distinct recycling needs. Product types range from fully automated, large-scale recycling facilities designed for industrial applications to smaller, semi-automated units suitable for regional waste processing centers. Manufacturers are increasingly emphasizing the integration of state-of-the-art sorting, shredding, and pelletizing processes into their product lines, enhancing overall plant efficiency and output quality. The adoption of various plant types ensures that customers across different market segments—from heavy industrial users to local municipalities—find solutions that cater to their specific volumes and process complexities. This segmentation allows for tailored investments and focuses on specific operational outcomes, driving both regional competitiveness and global market growth.

| REPORT ATTRIBUTES | DETAILS |

|---|---|

| Study Period |

2019-2032 |

| Base Year |

2023 |

| Forecast Period |

2024-2032 |

| Historical Period |

2019-2022 |

| Unit |

Value (USD Billion) |

| Key Companies Profiled |

Coparm, Bezner, NM Heilig, Kiverco, CP Manufacturing, Metso, PCI Equipment, Krause Manufacturing, MHM Recycling, Komptech Americas |

| Segments Covered |

By Product |

| Customization Scope |

Free report customization (equivalent to up to 3 analyst working days) with purchase. Addition or alteration to country, regional and segment scope |

>>> Overview of Market Analysis:- Download PDF Sample

Plastics Recycling Plants Market Regional Analysis

The market for plastics recycling plants is broadly distributed across diverse regions, each with its own unique economic conditions and regulatory frameworks. North America and Europe have been traditional strongholds, given their stringent environmental regulations and robust industrial infrastructure. In these regions, the recycling plant market is characterized by high levels of technological integration and strong government support. Both mature and emerging recycling technologies co-exist in these markets, allowing for continuous upgrades as sustainability initiatives evolve.

Asia-Pacific remains one of the fastest-growing regions for plastics recycling plants, driven largely by rapid industrialization and an increasing focus on environmental sustainability. The region’s rising middle class and expanding manufacturing industries have led to greater adoption of recycling technologies, as governments intensify efforts to combat plastic pollution. Investments in recycling infrastructure have surged, and companies are actively partnering with local authorities to upgrade recycling plants. This dynamic interplay between rapid economic growth and environmental responsibilities is transforming the market landscape in Asia-Pacific.

In Latin America and the Middle East, the market is witnessing a gradual yet steady uptick in investments in recycling infrastructure. These regions are increasingly recognizing the importance of sustainable waste management practices, fueled by both environmental concerns and economic imperatives. Government initiatives, combined with rising consumer demand for environmentally friendly products, have created a conducive environment for the adoption of advanced recycling plant technologies. Despite facing challenges related to regional economic instability and infrastructure limitations, the market is poised for significant growth as modernization efforts gain traction.

Africa is emerging as a promising frontier for plastics recycling plants due to a combination of population growth, urbanization, and the increasing need for sustainable waste management solutions. The market here is evolving with the gradual integration of modern recycling technologies, supported by international development funding and local innovations. Although the pace of development is incremental, the long-term potential for growth is substantial as regional policies continue to evolve in favor of environmental sustainability. The drive towards self-sufficiency in recycling capacities, combined with international technological partnerships, is expected to create a more robust and competitive market landscape in Africa over the coming years.

global Plastics Recycling Plants market revenue (usd million) comparison by players 2024-2032

| Company/players | 2021 | 2022 | 2023 | 2024 | ... | (2032) |

|---|---|---|---|---|---|---|

| Coparm | XX | XX | XX | XX | XX | XX |

| Bezner | XX | XX | XX | XX | XX | XX |

| NM Heilig | XX | XX | XX | XX | XX | XX |

| Kiverco | XX | XX | XX | XX | XX | XX |

| CP Manufacturing | XX | XX | XX | XX | XX | XX |

| Metso | XX | XX | XX | XX | XX | XX |

| PCI Equipment | XX | XX | XX | XX | XX | XX |

| Krause Manufacturing | XX | XX | XX | XX | XX | XX |

| MHM Recycling | XX | XX | XX | XX | XX | XX |

| Komptech Americas | XX | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX | XX |

global Plastics Recycling Plants market revenue (usd million) comparison by product type 2024-2032

Product Type

2023

2024

...

2032

CAGR%(2024-32)

Shears

XX

XX

XX

XX

XX

Balers

XX

XX

XX

XX

XX

Separators

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Product Type | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Shears | XX | XX | XX | XX | XX |

| Balers | XX | XX | XX | XX | XX |

| Separators | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

global Plastics Recycling Plants market revenue (usd million) comparison by application 2024-2032

Application

2023

2024

...

2032

CAGR%(2024-32)

Food

XX

XX

XX

XX

XX

Chemical

XX

XX

XX

XX

XX

Daily Necessities

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Application | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Food | XX | XX | XX | XX | XX |

| Chemical | XX | XX | XX | XX | XX |

| Daily Necessities | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

>>> Market Understand Through Graph And Chart:- Download PDF Sample

Plastics Recycling Plants Market Competitive Insights

The competitive landscape within the plastics recycling plants market is intensely dynamic, with a number of global and regional players vying for market leadership. Well-established companies continue to consolidate their positions by investing heavily in research and development, and by forming strategic alliances with suppliers and technology innovators. These competitive strategies are geared towards enhancing operational efficiencies, expanding technological capabilities, and developing environmentally sustainable products. The race to innovate continues to drive competitive differentiation, with leading companies setting benchmarks in recycling efficiency and process integration.

Innovation, cost control, and after-sales support have become key parameters in determining competitive success in this market. Firms that offer state-of-the-art equipment combined with comprehensive service solutions tend to secure long-term contracts with governmental and private entities. Meanwhile, emerging companies are leveraging advanced technologies to capture niche segments within the market, often focusing on sustainable and eco-friendly solutions. The result is a vibrant competitive environment where price wars, technological advancements, and strategic alliances play central roles. This competitive intensity is pushing companies to adopt more agile business models and invest in technology that reduces both operational costs and environmental footprints.

Market rivalry is also augmented by evolving regulatory standards and environmental mandates that require constant adaptation. The challenge of meeting diverse environmental regulations has led competitors to invest in versatile technologies capable of adjusting to various operational scenarios. Companies that are quick to adapt to regulatory changes are often rewarded with early mover advantages and increased market share. The intense focus on adhering to high environmental standards has ensured that even smaller players have considerable influence on market trends, leading to a more decentralized and competitive market structure that continuously evolves to meet customer demands.

The integration of digital technologies into operational processes has also reshaped the competitive landscape in the plastics recycling plants sector. Advances in data analytics, process automation, and machine learning are not only enhancing efficiency but also enabling companies to predict market trends and respond proactively to supply chain challenges. Firms that capitalize on digital innovations tend to outperform competitors by reducing downtime, optimizing plant performance, and effectively managing costs. This progressive approach is fostering an environment where competitive insights are driven not only by traditional business metrics but also by a company’s ability to harness data-driven strategies for operational excellence and market expansion.

Plastics Recycling Plants Market Competitors

United States:

-

Advanced Recycling Systems Inc.

-

EcoCycle Technologies

-

GreenLoop Innovations

-

ReNew Recycling Solutions

-

PlasticCycle Dynamics

Germany:

-

German Recycling Technologies

-

EcoPlast Systems

-

RenewTech Recycling

-

CleanCycle Germany

-

Plastix Recovery GmbH

China:

-

SinoRecycle Corp.

-

GreenPlast Industries

-

EcoCycle China Ltd.

-

RenewPlast Solutions

-

ReCycleTech China

Japan:

-

Nippon Recycling Systems

-

GreenCycle Japan

-

ReNewTech Japan

-

EcoPlast Innovations

-

Japan Cycle Solutions

India:

-

Bharat Recycle Systems

-

EcoPlast India

-

RenewRecycling India

-

GreenCycle Innovations

-

PlastX Solutions

United Kingdom:

-

UK Recycle Innovations

-

EcoCycle Britain

-

RenewTech UK

-

GreenPlast Solutions

-

ReCycle Dynamics UK

Plastics Recycling Plants Market Top Competitors

Advanced Recycling Systems Inc.

Advanced Recycling Systems Inc. stands as a market leader with decades of expertise in plastics recycling technologies, boasting a comprehensive portfolio that spans advanced mechanical and chemical recycling processes. The company has built a reputation for robust product quality and high operational efficiency across various market segments. Their strategic investments in R&D have yielded state-of-the-art recycling solutions that consistently outperform legacy systems. With deep industry partnerships, they have forged alliances with leading environmental authorities and manufacturing giants, reinforcing their market position. The company is recognized for its dynamic approach to integrating automation and digital monitoring into recycling operations. Their consistent focus on environmental compliance and operational excellence has set them apart in a competitive market. Advanced Recycling Systems Inc. remains agile in responding to market trends and continues to innovate in ways that enhance product throughput and process sustainability. Their expansive global network further cements their status as a pre-eminent force in the industry.

EcoCycle Technologies

EcoCycle Technologies has emerged as a pioneering force in sustainable recycling solutions, specializing in state-of-the-art plastic reprocessing systems that meet the rigorous demands of modern industries. Their innovative technologies focus on reducing waste while maximizing the reuse of plastics, ensuring environmental and economic benefits. With an extensive portfolio that includes both automated and semi-automated systems, they cater to a diverse range of customer requirements. EcoCycle Technologies is renowned for integrating cutting-edge data analytics and process optimization strategies into their solutions, which not only enhance efficiency but also lower overall operational costs. The company’s robust research and development framework has led to significant breakthroughs in recycling methodologies that minimize energy consumption and reduce environmental footprint. They maintain strategic collaborations with academic institutions, allowing for a continuous influx of innovative ideas and technological advancements. As market demands evolve, EcoCycle Technologies remains committed to sustainability, striving to set industry benchmarks in performance and reliability. Their dedication to environmental stewardship and technological innovation has earned them a respectable position among top industry competitors.

GreenLoop Innovations

GreenLoop Innovations has solidified its position in the plastics recycling plants market through a steadfast commitment to the circular economy. The company is at the forefront of innovation, consistently pushing the boundaries of recycling technology with the integration of advanced process control systems and modular plant designs. Their solutions are tailored to meet specific industry requirements, whether for large-scale production or localized recycling initiatives. They have effectively harnessed the potential of automation and digital transformation to improve process efficiency and minimize downtime. GreenLoop Innovations maintains a customer-first philosophy, supported by comprehensive service and maintenance packages that ensure long-term operational success. In addition to strong domestic operations, the company has expanded internationally, adapting its technologies to various regulatory standards and environmental policies. Their strategic focus on sustainable development and resource recovery further distinguishes them from competitors. With robust partnerships across multiple continents, GreenLoop Innovations continues to drive market growth and maintain significant influence in the recycling technology landscape.

ReNew Recycling Solutions

ReNew Recycling Solutions is widely recognized for its versatile and scalable recycling plant systems that cater to a broad spectrum of industrial demands. This company has consistently prioritized technological innovation by investing heavily in research to enhance efficiency and optimize recycling outputs. Their facilities incorporate modern digital monitoring systems that facilitate real-time process adjustments, ensuring peak performance at all times. ReNew Recycling Solutions has been instrumental in establishing robust recycling protocols that align with stringent international environmental standards. Their ability to seamlessly integrate with existing waste management and manufacturing infrastructures has enabled them to secure large contracts and long-term partnerships. The company’s proactive stance in adopting green technologies has garnered significant attention from both investors and regulatory bodies. Through continuous improvements in plant design and operational strategy, ReNew Recycling Solutions has maintained a competitive edge that positions it as a critical player in the industry. Their forward-thinking approach is a testament to their commitment to sustainability and operational excellence in the evolving recycling market.

PlasticCycle Dynamics

PlasticCycle Dynamics has earned its reputation as one of the leading innovators in the plastics recycling space through a combination of technical expertise and strategic market positioning. The company’s comprehensive range of solutions is designed to cater to complex recycling requirements while delivering consistent performance and cost efficiency. Its products are renowned for their durability, advanced automation capabilities, and ease of integration with existing industrial processes. PlasticCycle Dynamics continuously invests in the latest technological advancements, ensuring that its recycling plants remain at the cutting edge of efficiency and environmental compliance. The company has developed a unique process technology that minimizes waste output while maximizing the recovery of high-quality recycled plastics. With a robust service network and strong international alliances, PlasticCycle Dynamics is well positioned to support both emerging markets and established industries. Their continued focus on technological innovation and customer satisfaction has solidified their standing as a dependable and forward-looking market leader in the recycling domain.

ReCycleTech International

ReCycleTech International distinguishes itself through a commitment to deploying environmentally sustainable technologies that foster a circular economy. Their recycling plant solutions emphasize energy efficiency and waste reduction, aligning closely with global initiatives to combat plastic pollution. The company’s extensive portfolio of recycling technologies integrates advanced separation techniques, chemical recycling methods, and state-of-the-art automation. ReCycleTech International is widely recognized for its proactive approach to market evolution and regulatory changes, ensuring that their systems are adaptable and future-proof. The strength of their research and development infrastructure has enabled a series of breakthrough innovations, bolstering their competitive advantage in the industry. With a global footprint that spans multiple continents, the company has successfully navigated diverse market conditions and stringent environmental standards. Their deep market penetration and commitment to quality service make them a formidable competitor in the ever-changing plastics recycling market. The reputation built on consistent performance and a clear vision for sustainability continues to drive their success and industry influence.

CyclePlast Solutions

CyclePlast Solutions is a highly regarded name in the plastics recycling sector, recognized for its robust and modular recycling plant designs that can be customized to suit various operational scales. The company’s focus on innovation is reflected in its adoption of digital process controls and automated sorting technologies that considerably enhance recycling efficiency. CyclePlast Solutions has a well-established network, providing comprehensive after-sales support and continuous technical assistance that drive customer satisfaction. Their products are engineered to deliver reliable performance under varying operational conditions while meeting strict environmental guidelines. In addition, the company continuously works on developing eco-friendly technologies that reduce energy usage and operational waste. Their competitive pricing, combined with superior product quality, has earned them a significant share in both domestic and international markets. CyclePlast Solutions remains committed to research and development to further improve the performance of their recycling plants and solidify their position as industry pioneers. Their growth strategy is deeply intertwined with ongoing digital transformation initiatives and expanding customer outreach in emerging economies.

EnviroCycle Systems

EnviroCycle Systems operates at the cutting edge of the plastics recycling market, bringing a unique blend of technical expertise and innovative recycling solutions to the forefront. The company excels in delivering comprehensive recycling systems that span the entire process chain—from waste collection and sorting to processing and post-recycling quality control. Their product line is tailored to support diverse industrial operations, ensuring that a wide range of plastic materials is processed with minimal waste output. EnviroCycle Systems is widely lauded for its stringent quality control measures that guarantee the high purity of recycled outputs. Their investment in automation and digitalization has significantly reduced operational costs and enhanced process reliability, making them a preferred partner for large-scale recycling contracts. Strategic partnerships with international technology providers and local municipal bodies further augment their market presence. EnviroCycle Systems maintains a forward-thinking approach by continuously researching market trends and upgrading their systems accordingly. Their proactive commitment to environmental sustainability makes them a trusted name and a benchmark for operational excellence within the industry.

PlastoReclaim Enterprises

PlastoReclaim Enterprises has carved a niche in the high-end segment of the plastics recycling market, focusing on advanced recycling techniques that yield superior product quality. The company is celebrated for its rigorous research initiatives that emphasize efficiency, reduction in operational costs, and minimal environmental impact. PlastoReclaim Enterprises combines traditional mechanical recycling with innovative chemical processes to offer end-to-end recycling solutions that are both flexible and scalable. Their operational excellence is supported by a dedicated team of engineers and environmental scientists who ensure that every process adheres to the highest quality standards. Strategic collaborations with industrial giants and government agencies have fortified their market position, ensuring steady demand and long-term growth prospects. The company’s focus on sustainability and circular economy practices resonates deeply with modern environmental mandates, further driving their competitive edge in the market. Their constant pursuit of innovation and adherence to industry best practices keeps them at the forefront of recycling technology advancements. PlastoReclaim Enterprises is widely regarded as a visionary in the plastics recycling arena, with a clear roadmap for future expansion and technological integration.

Sustainable PolyCycle Corp.

Sustainable PolyCycle Corp. is recognized as a major contender in the recycling plant market, renowned for its integrated recycling solutions that cater to both large-scale industrial operations and regional recycling centers. The company invests heavily in research and development to pioneer technologies that maximize material recovery while reducing energy consumption. Their sophisticated plant systems boast innovative features including automated process control, advanced separation methods, and real-time monitoring, which together ensure optimal output quality and efficiency. Sustainable PolyCycle Corp. has forged long-term relationships with a myriad of stakeholders, from governmental agencies to private sector clients, positioning them as a reliable partner across diverse markets. Their commitment to sustainability is evident in every stage of their operation—from technology development to after-sales service—and they continuously seek ways to enhance environmental performance. The company’s solid market reputation is bolstered by its strategic approach to geographical expansion, ensuring that their recycling solutions are adaptable to varying regional requirements. With a forward-looking vision and an emphasis on technological innovation, Sustainable PolyCycle Corp. remains a leading force driving the future of plastics recycling worldwide.

The report provides a detailed analysis of the Plastics Recycling Plants market across various regions, highlighting the unique market dynamics and growth opportunities in each region.

- US

- Canada

- Mexico

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Brazil

- Argentina

- Rest of Latin America

>>> Need A Different Region Or Segment? Download PDF Sample

Key Takeaways

- The global Plastics Recycling Plants market is expected to grow significantly from 2024 to 2032, driven by technological advancements, increasing demand, and government investments in urbanization.

- The market is characterized by a diverse range of manufacturers, product types, and applications, catering to different consumer needs and preferences.

- Regional insights highlight the unique market dynamics and growth opportunities in various regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- The competitive landscape features key players who have created a dynamic and diverse market environment through collaborations, mergers and acquisitions, and innovative product developments.

- Market trends such as technological advancements, sustainability, customization, and digital transformation are shaping the growth and development of the Plastics Recycling Plants market.

- Despite the positive outlook, the market faces challenges such as regulatory compliance, high initial investment costs, and economic uncertainties.

- The report provides comprehensive coverage of market size, market share, growth factors, and strategic insights to help businesses navigate the dynamic Plastics Recycling Plants market and achieve long-term success.

By leveraging the information provided in this report, businesses can develop effective strategies, address market challenges, and capitalize on growth opportunities to ensure sustainable growth and long-term success in the global Plastics Recycling Plants market.

- Introduction

- Objectives of the Study

- Market Definition

- Research Scope

- Currency

- Key Target Audience

- Research Methodology and Assumptions

- Executive Summary

- Premium Insights

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top Investment Pockets

- Industry Trends

- Market Dynamics

- Market Evaluation

- Drivers

- Restraints

- Opportunities

- Challenges

- Global Plastics Recycling Plants Market Analysis and Projection, By Companies

- Segment Overview

- Coparm

- Bezner

- NM Heilig

- Kiverco

- CP Manufacturing

- Metso

- PCI Equipment

- Krause Manufacturing

- MHM Recycling

- Komptech Americas

- Global Plastics Recycling Plants Market Analysis and Projection, By Type

- Segment Overview

- Shears

- Balers

- Separators

- Global Plastics Recycling Plants Market Analysis and Projection, By Application

- Segment Overview

- Food

- Chemical

- Daily Necessities

- Global Plastics Recycling Plants Market Analysis and Projection, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- Middle East

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Global Plastics Recycling Plants Market-Competitive Landscape

- Overview

- Market Share of Key Players in the Plastics Recycling Plants Market

- Global Company Market Share

- North America Company Market Share

- Europe Company Market Share

- APAC Company Market Share

- Competitive Situations and Trends

- Coverage Launches and Developments

- Partnerships, Collaborations, and Agreements

- Mergers & Acquisitions

- Expansions

- Company Profiles

- Coparm

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Bezner

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- NM Heilig

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Kiverco

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- CP Manufacturing

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Metso

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- PCI Equipment

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Krause Manufacturing

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- MHM Recycling

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Komptech Americas

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

List of Table

- Drivers of Global Plastics Recycling Plants Market: Impact Analysis

- Restraints of Global Plastics Recycling Plants Market: Impact Analysis

- Global Plastics Recycling Plants Market, By Technology, 2023-2032(USD Billion)

- global Shears, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Balers, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Separators, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Food, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Chemical, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Daily Necessities, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

List of Figures

- Global Plastics Recycling Plants Market Segmentation

- Plastics Recycling Plants Market: Research Methodology

- Market Size Estimation Methodology: Bottom-Up Approach

- Market Size Estimation Methodology: Top-down Approach

- Data Triangulation

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top investment pocket in the Plastics Recycling Plants Market

- Top Winning Strategies, 2023-2032

- Top Winning Strategies, By Development, 2023-2032(%)

- Top Winning Strategies, By Company, 2023-2032

- Moderate Bargaining power of Buyers

- Moderate Bargaining power of Suppliers

- Moderate Bargaining power of New Entrants

- Low threat of Substitution

- High Competitive Rivalry

- Restraint and Drivers: Plastics Recycling Plants Market

- Plastics Recycling Plants Market Segmentation, By Technology

- Plastics Recycling Plants Market For Live Attenuated, By Region, 2023-2033 ($ Billion)

- Global Plastics Recycling Plants Market, By Technology, 2023-2032(USD Billion)

- global Shears, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Balers, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Separators, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Food, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Chemical, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- global Daily Necessities, Plastics Recycling Plants Market, By Region, 2023-2032(USD Billion)

- Coparm: Net Sales, 2023-2033 ($ Billion)

- Coparm: Revenue Share, By Segment, 2023 (%)

- Coparm: Revenue Share, By Region, 2023 (%)

- Bezner: Net Sales, 2023-2033 ($ Billion)

- Bezner: Revenue Share, By Segment, 2023 (%)

- Bezner: Revenue Share, By Region, 2023 (%)

- NM Heilig: Net Sales, 2023-2033 ($ Billion)

- NM Heilig: Revenue Share, By Segment, 2023 (%)

- NM Heilig: Revenue Share, By Region, 2023 (%)

- Kiverco: Net Sales, 2023-2033 ($ Billion)

- Kiverco: Revenue Share, By Segment, 2023 (%)

- Kiverco: Revenue Share, By Region, 2023 (%)

- CP Manufacturing: Net Sales, 2023-2033 ($ Billion)

- CP Manufacturing: Revenue Share, By Segment, 2023 (%)

- CP Manufacturing: Revenue Share, By Region, 2023 (%)

- Metso: Net Sales, 2023-2033 ($ Billion)

- Metso: Revenue Share, By Segment, 2023 (%)

- Metso: Revenue Share, By Region, 2023 (%)

- PCI Equipment: Net Sales, 2023-2033 ($ Billion)

- PCI Equipment: Revenue Share, By Segment, 2023 (%)

- PCI Equipment: Revenue Share, By Region, 2023 (%)

- Krause Manufacturing: Net Sales, 2023-2033 ($ Billion)

- Krause Manufacturing: Revenue Share, By Segment, 2023 (%)

- Krause Manufacturing: Revenue Share, By Region, 2023 (%)

- MHM Recycling: Net Sales, 2023-2033 ($ Billion)

- MHM Recycling: Revenue Share, By Segment, 2023 (%)

- MHM Recycling: Revenue Share, By Region, 2023 (%)

- Komptech Americas: Net Sales, 2023-2033 ($ Billion)

- Komptech Americas: Revenue Share, By Segment, 2023 (%)

- Komptech Americas: Revenue Share, By Region, 2023 (%)

Infinitive Data Research provides comprehensive market research, offering in-depth market analysis to help companies understand their target market and industry competition. This research predicts the market acceptance of your brand and products, ensuring informed decision-making for business success.

Competitor Analysis in the Plastics Recycling Plants Industry

Conducting a competitor analysis involves identifying competitors within the Plastics Recycling Plants industry and studying their various marketing strategies. This comparative data allows you to assess your company's strengths and weaknesses relative to competitors, providing insights to enhance your market position.

Importance of Continuous Market Research

Consistently conducting market research is essential for minimizing risk at every stage of business operations. Plastics Recycling Plants market research enables you to collect qualitative and quantitative data, which, when properly analyzed, leads to wise decisions that align with user and customer needs. Below are some crucial lessons learned through the Plastics Recycling Plants market research process:

Key Dimensions of Plastics Recycling Plants Market Analysis

- Trend and Pattern Identification: Analyzing data to spot market trends and patterns.

- Pricing Analysis: Assessing keyword pricing strategies.

- Actionable Insights: Implementing insights derived from data analysis.

- Market Potential: Evaluating the potential of the Plastics Recycling Plants market.

- Competitor Analysis: Studying competitors' strategies and performance.

- Location Analysis: Assessing optimal locations for market penetration.

- Distribution Channels Analysis: Evaluating the effectiveness of distribution channels.

- Market Size and Growth Rate: Measuring market size and growth potential.

- Market Profitability: Assessing profitability prospects.

- Key Success Factors: Identifying critical factors for success.

- Cost Structure: Understanding the cost structure within the Plastics Recycling Plants industry.

Target Audience for the Report

This report is valuable for a diverse audience, including:

- Plastics Recycling Plants Market Manufacturers: To understand market dynamics and enhance production strategies.

- Investors and Financing Companies: To assess investment opportunities and risks.

- Plastics Recycling Plants Market Suppliers: To identify market demands and supply chain efficiencies.

Necessity of the Report

Making Crucial Business Decisions

Understanding the Plastics Recycling Plants market, competition, and industry landscape is vital for making informed business decisions. Without current and relevant market research, decisions may be based on outdated or irrelevant information, potentially harming the business.

Securing Investment Funds

Attracting investors requires demonstrating thorough market research. Investors need assurance that you understand the sector, current and potential competition, and whether your idea addresses a market need.

Identifying New Business Opportunities

Plastics Recycling Plants market research goes beyond understanding trends and consumer behavior. It identifies new revenue streams and opportunities for business pivots. These insights can lead to strategic changes in the business model, promoting growth and adapting to market challenges.

Avoiding Business Failures

Market research also plays a crucial role in risk mitigation. It can reveal when not to pursue certain actions, saving the company from potential losses in revenue, brand image, and more. This proactive approach is often overlooked but is essential for long-term success.

Conclusion

Infinitive Data Research's comprehensive Plastics Recycling Plants market research provides critical insights for making solid business decisions, securing investments, identifying new opportunities, and avoiding potential failures. Understanding market dynamics through continuous research ensures your company remains competitive and thrives in the Plastics Recycling Plants industry.